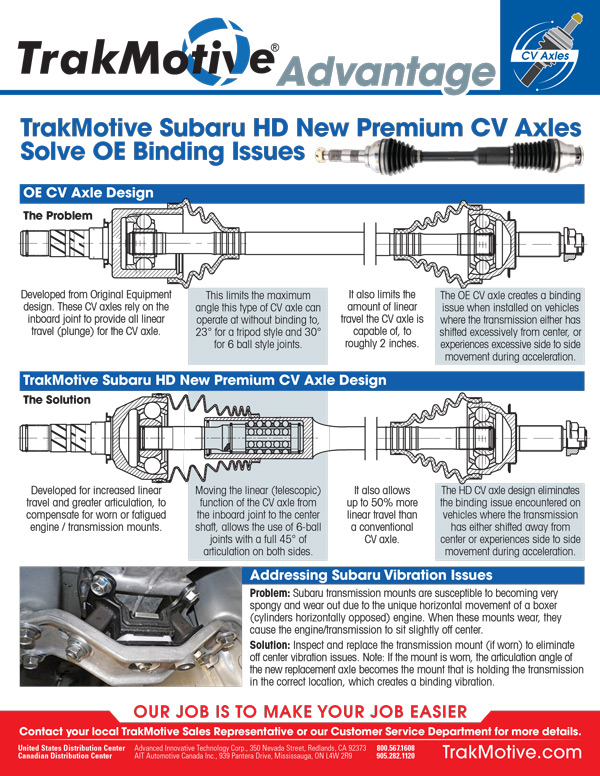

The Problem

Developed from Original Equipment design. These CV axles rely on the inboard joint to provide all linear travel (plunge) for the CV axle. This limits the maximum angle this type of CV axle can operate at without binding to, 23° for a tripod style and 30° for 6 ball style joints. It also limits the amount of linear travel the CV axle is capable of, to roughly 2 inches. The OE CV axle creates a binding issue when installed on vehicles where the transmission either has shifted excessively from center, or experiences excessive side to side movement during acceleration

The Solution

Developed for increased linear travel and greater articulation, to compensate for worn or fatigued engine / transmission mounts. Moving the linear (telescopic) function of the CV axle from the inboard joint to the center shaft, allows the use of 6-ball joints with a full 45° of articulation on both sides. It also allows up to 50% more linear travel than a conventional CV axle. The HD CV axle design eliminates the binding issue encountered on vehicles where the transmission has either shifted away from center or experiences side to side movement during acceleration.

Addressing Subaru Vibration Issues

The Problem

Subaru transmission mounts are susceptible to becoming very spongy and wear out due to the unique horizontal movement of a boxer (cylinders horizontally opposed) engine. When these mounts wear, they cause the engine/transmission to sit slightly off center.

The Solution

Inspect and replace the transmission mount (if worn) to eliminate off center vibration issues. Note: If the mount is worn, the articulation angle of the new replacement axle becomes the mount that is holding the transmission in the correct location, which creates a binding vibration.